KIMBERLY ENGINEERING MOTOR CONTROL / DRIVE casino card games COURSES.

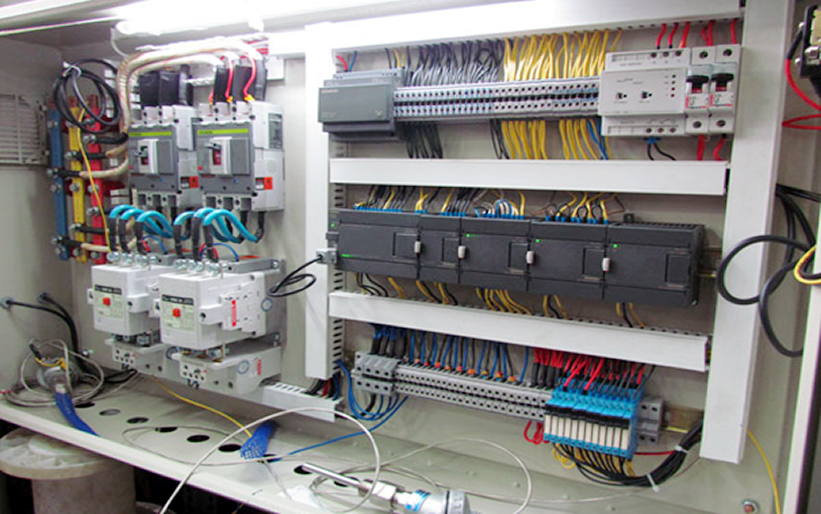

This course aims to provide participants with underpinning knowledge and skills needed to undertake electrical maintenance on motors and motor controls safely and efficiently. It exposes trainees to an extensive hands-on approach to wiring practices and troubleshooting of various control and power circuits utilized in the industrial controls of motors. Emphasis is also placed on safe working practice and on the development of useful practical skills in interpreting and troubleshooting ladder diagram circuits. Comprehensive course notes are provided.

COURSE TITLE

INDUSTRIAL MOTOR CONTROLS

COURSE CODE

KET103

DURATION

3 DAYS

Objectives:

- Understand and wire a wide range of devices (pushbuttons, relays, contactors, thermal overload, timers etc) and their principle of operation.

- Have an in-depth knowledge of how electric motors work

- Design and wire electric motor starters from scratch

- Use circuit diagram as an aid to design, replacement and maintenance

- Use electrical test equipment effectively and carry out testing of motors and motor starters

- Diagnose motor faults and recognize their associated symptoms

- Identify motor and control circuit fault using fault diagnosis and rectification techniques

- Practice safe working methods on electrical systems

COURSE CONTENT

- Identifying circuit symbols

- Understanding basic electrical symbols

- Logics of line diagrams

- Magnetic solenoid

- Relay and contactor numbering

- Time Delay relay

- Basic panel wiring techniques

- Selecting correct panel wiring cable

- Producing a basic motor control layout

- Installing a motor: The Rules

- Installing flexible conduit

- Examining Motor Nameplate

- Wiring Push-buttons, toggle switches, relays, contactors, timers, auxiliary contacts, overload relay

- Correctly setting an overload unit to suit the motor protected

- Installing a control circuit to provide Start / Stop operation

- Installing a control circuit to provide Emergency Stop operation

- Installing a control circuit to provide Auto / Off / Manual operation

- Installing a control circuit to provide Reversing, braking, jogging,

- Interlocking & Sequential operations

- Installing Power On, Motor Run and Overload Tripped indication

- Two-wire and three-wire controls

- Wiring a three-phase motor winding in Star and Delta

- Wiring a D.O.L. starter to control and protect a three-phase motor

- Wiring a D.O.L. starter to control and protect a single-phase motor

- Wiring a Wye-Delta starter to control and protect a three-phase motor

- Converting a three phase motor to single phase

- Developing and interpreting schematic diagrams for above circuits

- Locating and repairing faults on above circuits

- Introduction to Programmable Logic ControllersBasic VFD

- Safe working methods on electrical systems

In this training, participants will learn how to improve VFD control and efficiency, troubleshoot and fix VFD problems, reduce equipment downtime, eliminate chronic VFD problems, and lower cost of VFD operation.

COURSE TITLE

Variable Frequency Drives Set-up, Programming and Troubleshooting (DANFOSS & SIEMENS)

COURSE CODE

KET203

DURATION

– DAYS

Objectives

At the end of the training participants should be able to:

- Properly match a drive to a machine

- Choose the correct motor

- Choose the best type of VFD

- Correctly configure, operate and monitor drive systems

- Identify and correct configuration errors

- Identify & correct drive system problems

- Differentiate between drive faults, motor faults and power faults

- Perform start-up of an AC Drive

- Program and adjust the drive for desired operation

Course Content

- Why use a drive?

- AC motors operations and limitations

- Motor control circuits

- Interfacing VFDs

- Latching and Interlocking circuits

- Programming VFD parameters

- Communication with PLC

- Motor Starters: DOL, Star-Delta

- AC Drives and its applications

- Fault finding and troubleshooting

- Criteria for Drive Selection

- Designing Drive control panel

- Soft starter and its advantage over conventional starters

COURSE TITLE

CETIFICATE IN INDUSTRIAL AUTOMATION

COURSE CODE

KET604

DURATION

15 DAYS

Course contents include those of:

- KET 101

- KET 201

- KET 102

- KET 202

- KET 301

- KET 302

- KET 402

- KET 103

- KET 203